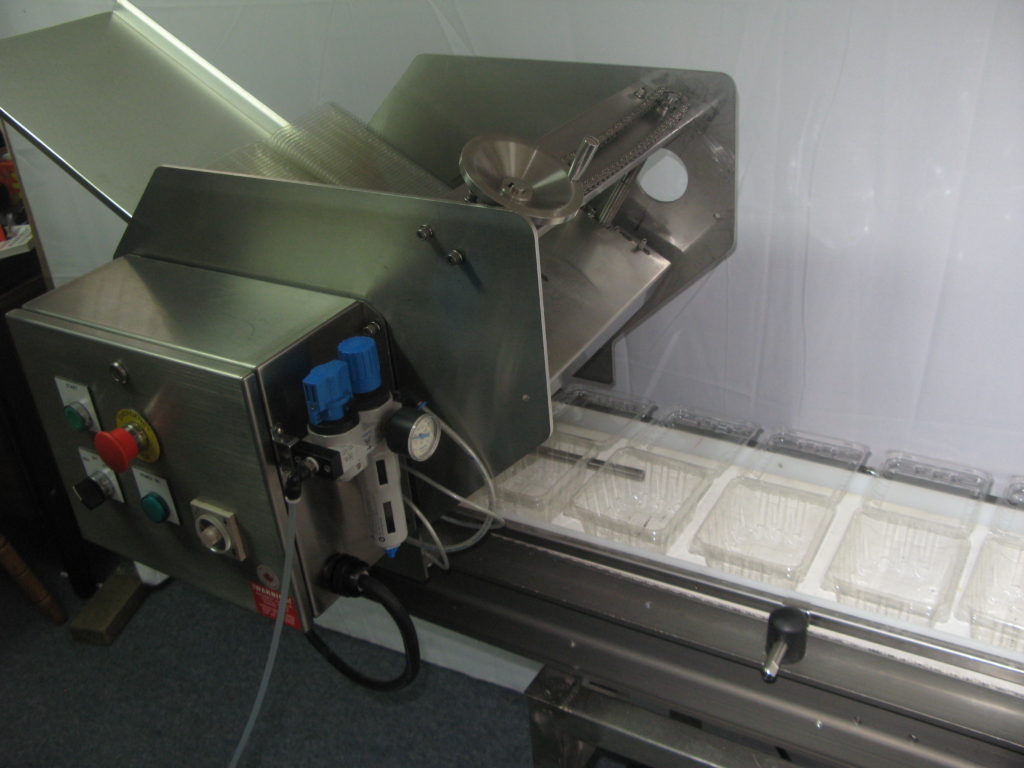

Food Tray Placer

For Versatile High-Speed Operation

Traypack Machine has developed new technology to separate and denest trays using a “pick & place” method. The Tray Placer picks trays from a magazine and places them down accurately onto a moving conveyor at high speeds. It provides a new standard of efficiency and economy for automation for customers using “top seal” or” over wrap” food packaging trays. The denester can be used on an array of different tray shapes and sizes with materials made of plastic, foam, paper and foil. For applications such as ready meals, soup, produce, meat, poultry, bakery, cookies, confectionery and nuts.

Denester with Cryovac Food Trays

Tray Placer Features

- Rugged Stainless Steel construction

- Suitable for clean room washdown conditions

- Unique tray separating system to pick and place or denest trays eliminating the need for vacuum and rotating or reciprocating mechanical arms normally used in “pick & place” equipment

- High speeds up to 90 trays per minute, single line

- Variable speed

- Safe and easy to operate and maintain

- Simple push button controls

- Quick and easy adjustment by the line operator for different tray sizes without the need of tools

- Compact design for simple installation mounting directly onto the packaging line conveyor

- CSA approved control panel - 110 volt/60 cycle/5 amps

- Pneumatic air supply - 60 psi. /5 cfm

Tray Placer Options

- Double lane - up to 180 trays per minute

- Electrical servo motor drives instead of pneumatic

- Floor stands for alternative mounting

- Custom applications

Denesting Square Aluminum Pans

Clam Shell Denester

Plastic Plate Placer

You are welcome to request our technical assessment of your plant needs and tray performance tests. Traypack machines are designed and manufactured in Canada, from durable stainless steel, with pneumatic or electric controls. Built to industry sanitation standards and C.S.A electric approved