Denesting Machines

Automatic Tray Packaging to help businesses in the packaging of:

- food

- bakery

- produce

- consumer products

- medical packaging

Reliable Denesting Machines for Tray Packaging Lines

Traypack Machine provides efficient reliable de-nesting automation with proven high speed technology for the food packaging industry. The equipment is easily adjustable by maintenance or production line employees for varying tray sizes and applications. They are built using stainless steel suitable for sterile and “clean room” wash down applications. Little maintenance requirements provide a cost effective, long term solution for de-nesting needs with a fast ROI.

Industries served by Traypack Machine’s solutions include fresh, frozen , and vacuum packed meat and poultry, ready-made meals, airline snacks, institutional meals, bakeries, confectioners and many other consumer product applications. Our de-nesters are suitable for use with a wide range of round and rectangular trays made of plastic, tin foil, pulp, cardboard and Styrofoam.

Multi-Tray Examples

Six trays at 300 Trays per minute

40 Years of Innovation

Traypack Machine Ltd. was one of the first companies in North America to develop “mechanical cam operated” pick and place de-nesting machinery for use with thermo-formed plastic trays over 40 years ago. Patents were issued in both Canada and the United States for these first designs. Our technology has grown and developed with exciting new designs to accommodate the large food packaging industry.

We Design and Manufacture Denesters and Tray Placers for Meat & Poultry, Bakery, Frozen, Fresh and Ready Made Foods, Candy, Medical & Pharmaceutical, Airline Meals and Institutional Meals

Our Denester Machines

90 Trays Per Minute

Traypack Machine’s latest de-nester is for the typical food tray production packaging operation. Designed to place one tray at a time onto the packaging conveyor line at speeds up to 90 trays per minute.

Featuring a “quick change” system for use with compatible trays of differing sizes. The Tray Placer is designed for online mounting, or available with a floor stand.

Complete with electric control panel for integration with automatic food packaging systems. Constructed entirely of stainless steel for safe, sterile wash down applications.

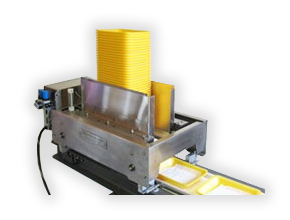

300 Trays Per Minute

Traypack Machine’s Multi-Tray Dropper De-nester is developed for applications that require two, three or four trays dropping simultaneously onto separate packaging lines, or for high volume applications, onto a single conveyor line.

The “six tray” model can operate at speeds up to 200 trays per minute. The Tray Dropper is designed for use with a typical vacuum or gas flush multi-pac operation. Complete with pneumatic and electric control panel to integrate with existing automated systems.

Constructed of stainless steel for clean room wash down conditions.

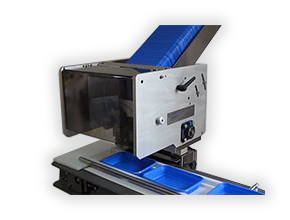

60 Trays Per Minute

Traypack Machine’s traditional Pick and Place De-nester is vacuum operated with a unique cam mechanism to pick one tray from a stack and place it accurately onto a conveyor line at speeds up to 60 trays per minute.

Ideal for use with tightly stacked thermo-formed plastic and clamshell trays. It features a 40″ magazine and comes with a C.S.A. approved electric control panel. Available optional floor stand and castors.

Constructed of stainless steel for normal wash down applications.

Plastic, paper & tin foil food trays

Customers Using Our Denesters