Our Denester Machines

90 Trays Per Minute

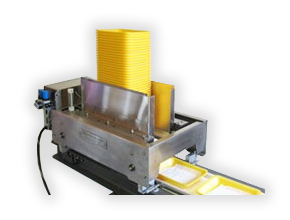

Traypack Machine’s latest de-nester is for the typical food tray production packaging operation. Designed to place one tray at a time onto the packaging conveyor line at speeds up to 90 trays per minute.

Featuring a “quick change” system for use with compatible trays of differing sizes. The Tray Placer is designed for online mounting, or available with a floor stand.

Complete with electric control panel for integration with automatic food packaging systems. Constructed entirely of stainless steel for safe, sterile wash down applications.

120 Trays Per Minute

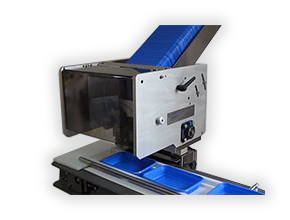

Traypack Machine’s Tray Dropper De-nester is developed for applications that require two, three or four trays dropping simultaneously onto separate packaging lines, or for high volume applications, onto a single conveyor line.

The “four tray” model can operate at speeds up to 200 trays per minute. The Tray Dropper is designed for use with a typical vacuum or gas flush multi-pac operation. Complete with pneumatic and electric control panel to integrate with existing automated systems.

Constructed of stainless steel for clean room wash down conditions.

60 Trays Per Minute

Traypack Machine’s traditional Pick and Place De-nester is vacuum operated with a unique cam mechanism to pick one tray from a stack and place it accurately onto a conveyor line at speeds up to 60 trays per minute.

Ideal for use with tightly stacked thermo-formed plastic and clamshell trays. It features a 40″ magazine and comes with a C.S.A. approved electric control panel. Available optional floor stand and castors.

Constructed of stainless steel for normal wash down applications.